Can Inspection

- Estás aquí:

- Inicio

- One Vision Inspection System Can Inspection

System features

360º inspection:- Detection of sealing defects, seaming defects, peaks, dents/deformations, tears, label control... etc.

- Speed up to 600 cans/minute

- Detection of micro perforations, lid displacement, marking defects, tongue or ring defects, deformations, product quality control... etc.

- Speed up to 900 cans/minute

Can Inspection Systems

Introduction:

Welcome to the future of production inspection with our can inspection systems. Our innovative machine vision system redefines the standards of accuracy in detecting micro-perforations and defects in can seals at speeds more than 10 units per second.

Outstanding Features:

Equipped with state-of-the-art technology, our system offers unparalleled accuracy in identifying micro-perforations, ensuring the integrity of each product.

Leveraging artificial intelligence capabilities, our system continuously learns and adapts, improving its performance over time.

Designed for high-speed production environments, this system can process more than 10 cans per second without compromising inspection quality.

Not even the smallest detail is missed. Our solution detects and classifies seal defects with an efficiency that surpasses any other system available on the market

The user-friendly interface allows for easy and fast control, even in fast-paced production environments. Claim some technical details of traceability.

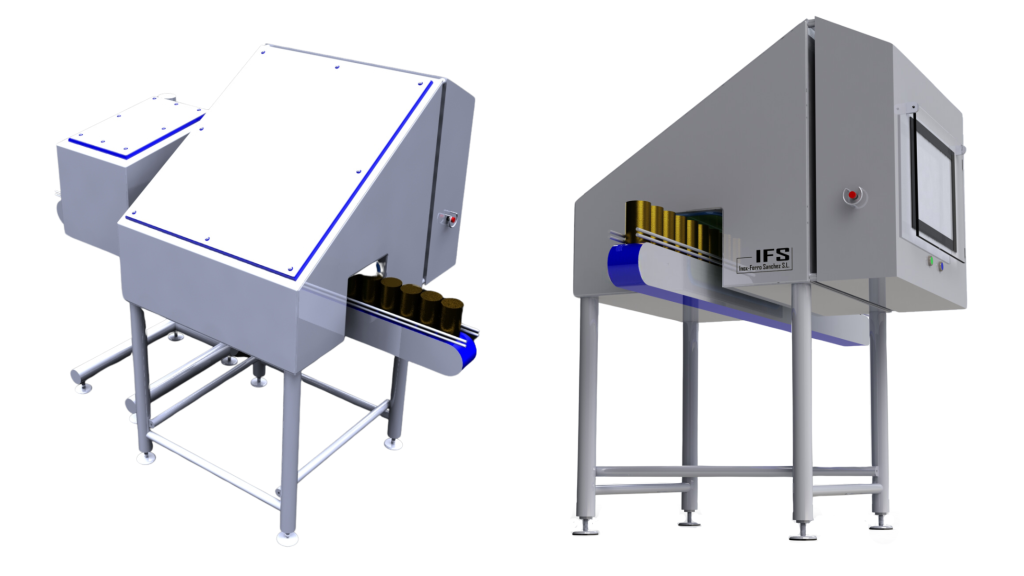

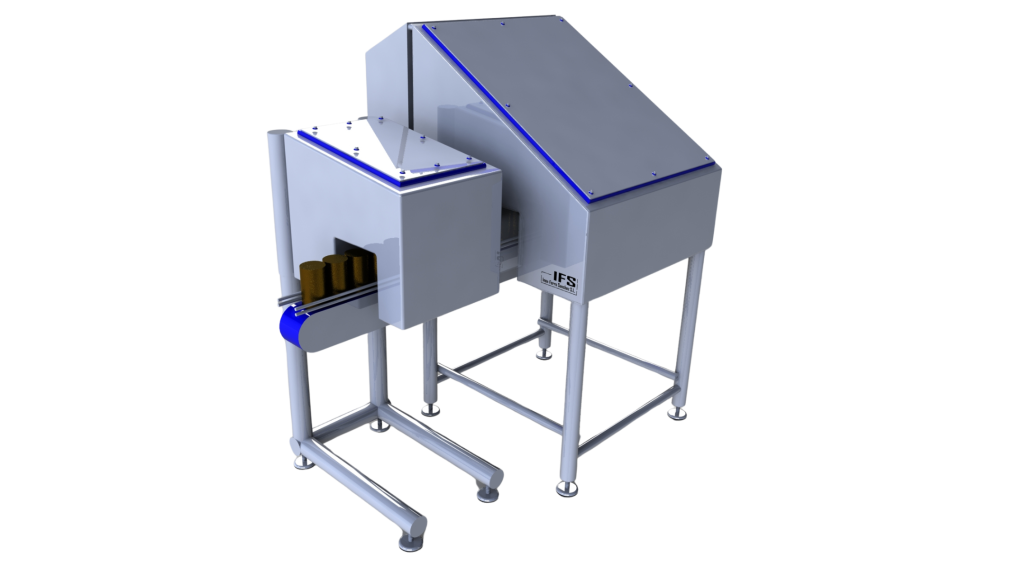

With a footprint of up to 1,800mm, it integrates easily into your production line. Equipped with up to 5 chambers, conveyor belt and in-line rejection system for non-conforming products. It offers a comprehensive solution to improve the quality and efficiency of your production.

Benefits to your Production:

Increased Efficiency:

Reduce downtime and increase productivity with accurate and fast inspection.

Quality Assurance:

Ensure the quality of every product, avoiding defects and minimizing risks associated with defective products.

Regulatory Compliance:

Meet the highest quality standards and regulations, ensuring customer satisfaction and regulatory compliance.

Trust Innovation, Trust Us:

With our machine vision system, your production line will reach new levels of efficiency and quality.

Find out how we can raise your inspection standard and ensure excellence in every can that leaves your production line.

Applications: