Tipper container in-line

- Estás aquí:

- Inicio

- Dumper and Tipper container solutions Tipper container in-line

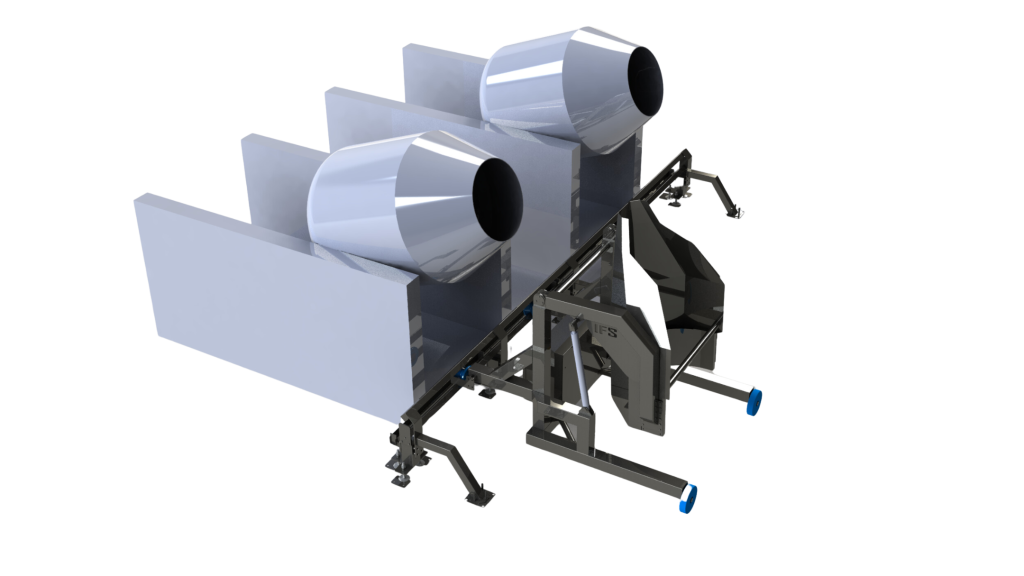

Tipper container in-line VCC-600 Features

- Dimensions (mm): 1400x1.200x135-880 mm

- Weight (Kg): 360 Kg

- Voltage (V/Hz): 380V / 50Hz

- Nominal working pressure (bar): 80-100 bar

- Load Capacity (Kg): Up to 850 Kg

Optimize your production process with the revolutionary I.F.S VCC-600 food product elevator-turner.

Our innovative system is designed to facilitate the transfer of product buckets, either frozen or fresh, into the production drum without loss of injection liquid to the floor. With hydraulic actuation by means of 2 pistons and IP69K protection panel, our tipper container can support loads up to 600Kg, ensuring the robustness and durability that its operation requires.

With the I.F.S VCC-600, we offer two installation options to suit your needs:

This system allows smooth and precise movement through the different tumblers in the production room. With mobile guides flush with the floor, we guarantee a constant distance between the tipper and the drum, ensuring a correct tipping of the product in each cycle.

For independent attachment per bass drum, we offer the option of direct interlocking. Although it requires the operator to position the dumper in front of each production drum, it ensures a secure and stable connection. Our interlocking system allows the dumper to be quickly fixed and levelled on the ground, without the need for additional civil works.

Both options are designed to provide maximum efficiency and convenience on your production line.

System advantages:

- Space saving and process simplification: by locating a single machine in line for different drums, without the need for additional tipping tables or conveyor belts.

- Improved process quality: by avoiding deterioration of the drum blades and contamination of the product with chips, common in belt conveyor systems.

- Reduced manpower required for operation: only one operator is required with the I.F.S VCC-600 system, compared to at least two people with belt conveyor systems.

Chose efficiency, quality, and safety with the I.F.S VCC-600 food product elevator-turner.

Applications: