Machinery tool storage trolleys

- Estás aquí:

- Inicio

- Storage Trolleys and Accessories Machinery tool storage trolleys

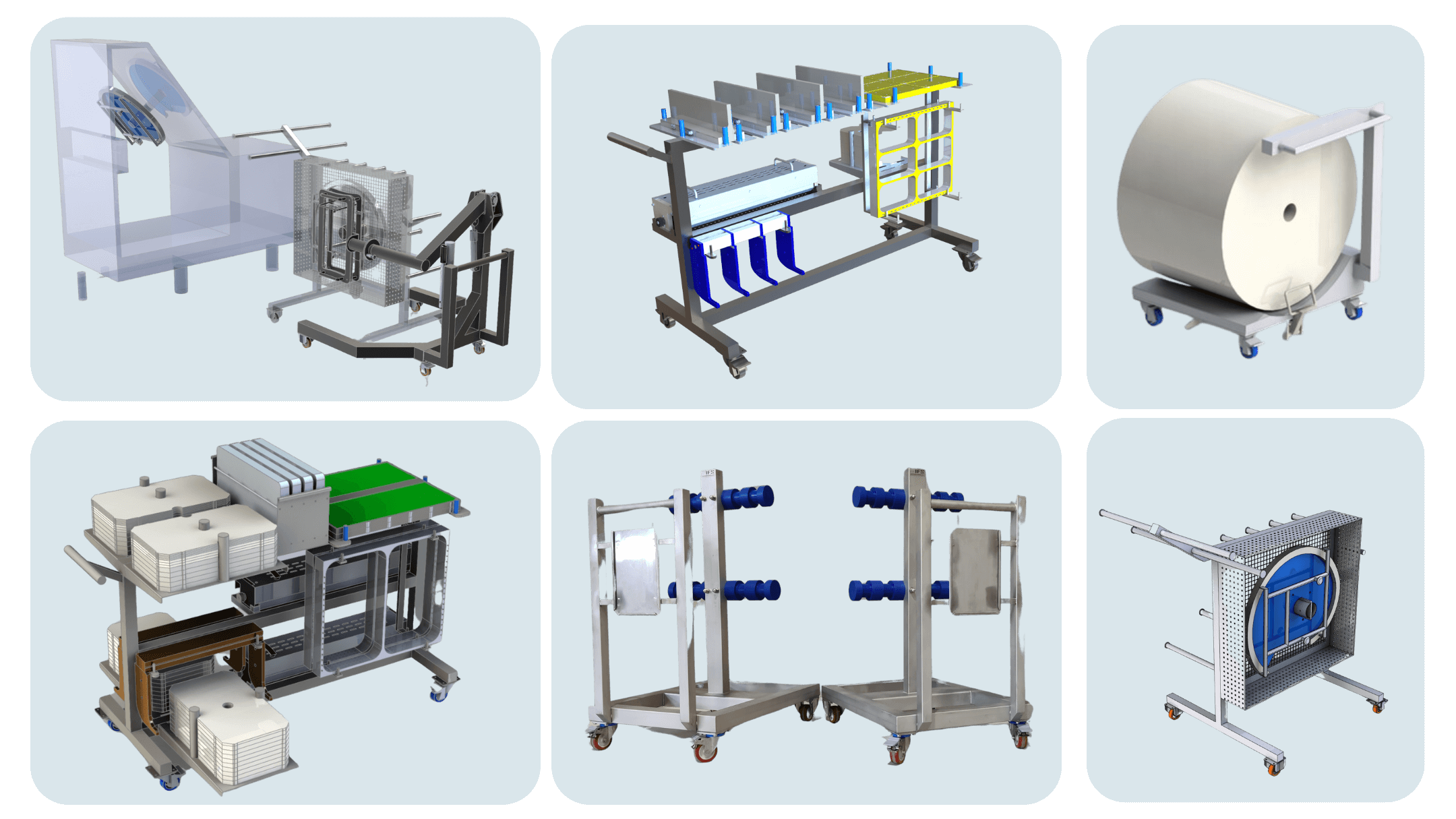

Wide variety of storage and cleaning trolleys

- Customized trolleys for storage of thermoforming and thermosealing tools

- Customized trolleys for storage and cleaning of cutting systems

- Food trolleys for transport and storage of food knives

- Trolleys for tool and parts cleaning

- Trolleys for food and pharmaceutical production accessories

Machinery tool storage trolleys

Tool storage carts for machinery are an invaluable tool in the context of 5S’s and Lean Manufacturing, as they play a crucial role in optimizing the work environment and continuous improvement in the company.

In our company, we specialize in the manufacture of trolleys designed specifically for the storage of tools for all types of machinery, thus complying with the rigorous requirements of 5S’s.

The 5S’s, which are Seiri (Sorting), Seiton (Organization), Seiso (Cleanliness), Seiketsu (Standardize) and Shitzuke (Keep improving), are the foundation of Lean Manufacturing and focus on creating an efficient and safe working environment.

1- Sorting (Seiri) involves identifying and sorting indispensable materials by taking inventories. This is where machine tool storage carts play a vital role by providing an organized system for storing and sorting these materials efficiently.

2- Organization (Seiton) involves arranging indispensable materials so that they are easily accessible to employees. Storage carts facilitate this task by providing designated compartments and assigned spaces for each type of material, which helps reduce search times and increase efficiency.

3- Cleanliness (Seiso) is another fundamental aspect of 5S’s and Lean Manufacturing. Removing dirt and keeping equipmet in optimal condition is essential to ensure a safe and productive work environment. Tool storage carts for machinery can incorporate features that facilitate cleaning and proper maintenance of stored materials and tools.

4- Standardization (Seiketsu) involves setting clear standards and distinguishing when the first three S’s are being applied correctly. Storage carts can help in this regard by providing a visually clear and consistent structure for the storage and organization of materials, which facilitates adherence to established standards.

5- Finally, keep improving (Shitzuke) involves a repetitive cycle of continuous evaluation and improvement to maintain a neat and clean work environment. Machine tool storage carts can adapt and evolve along with the company’s continuous improvement processes, allowing for constant optimization of workflow and operational efficiency.

In summary, machine tool storage carts are an essential tool for implementing 5S’s and Lean Manufacturing, as they contribute significantly to the optimization of the working environment, operational efficiency, and continuous improvement in the company. Their proper use not only increases productivity and quality, but also improves safety and staff satisfaction.