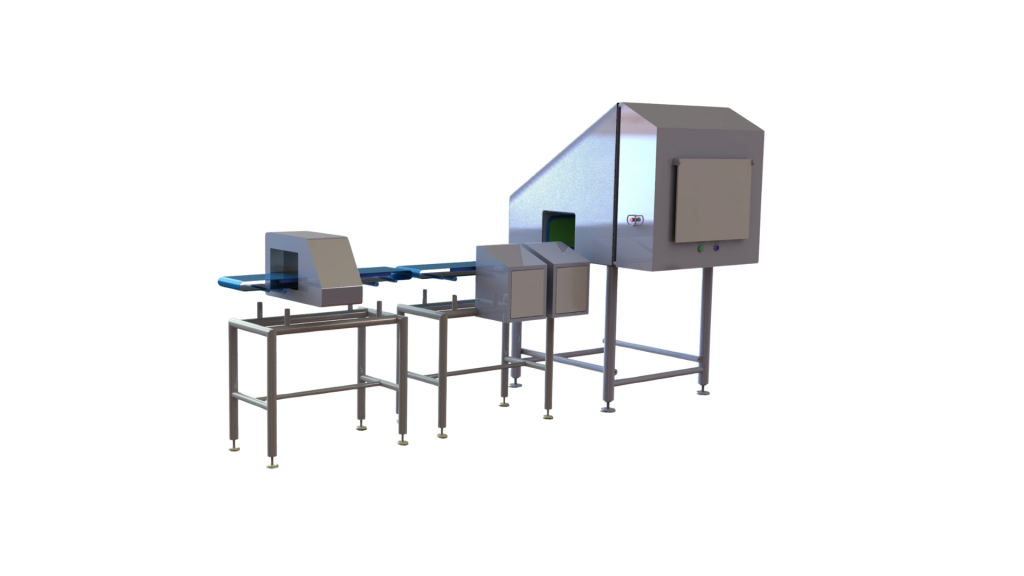

End of production line

- Estás aquí:

- Inicio

- End of Lines and Conveyor Belts End of production line

General Features

- Approximate length (mm): 2.550 - 3.850 mm

- Line capacity (containers/minute): 300 containers/minute

- What the line includes:

- Conveyor to individualize the product

- Conveyor with metal detection and/or X-ray with rejection

- Dynamic weighing with rejection

- OCR and container inspection system with Deep Learning AI with Rejection

Optimizing the End-of-Line Process with IFS

At IFS, we pride ourselves on offering complete and advanced end-of-line solutions, ensuring an efficient and high-quality production process every step of the way. From thermoformed exit to final product cartooning, our integrated system is designed to ensure maximum efficiency and safety, with a particular focus on quality controls and production flow optimization.

Thermoformer Exit:

Upon exiting the thermoformed, the individualized product is directed to the cartooning area via a specially designed conveyor belt to maintain product integrity and hygiene. Our conveyor features a robust stainless-steel chassis and a modular belt, ensuring smooth and reliable operation in demanding environments.

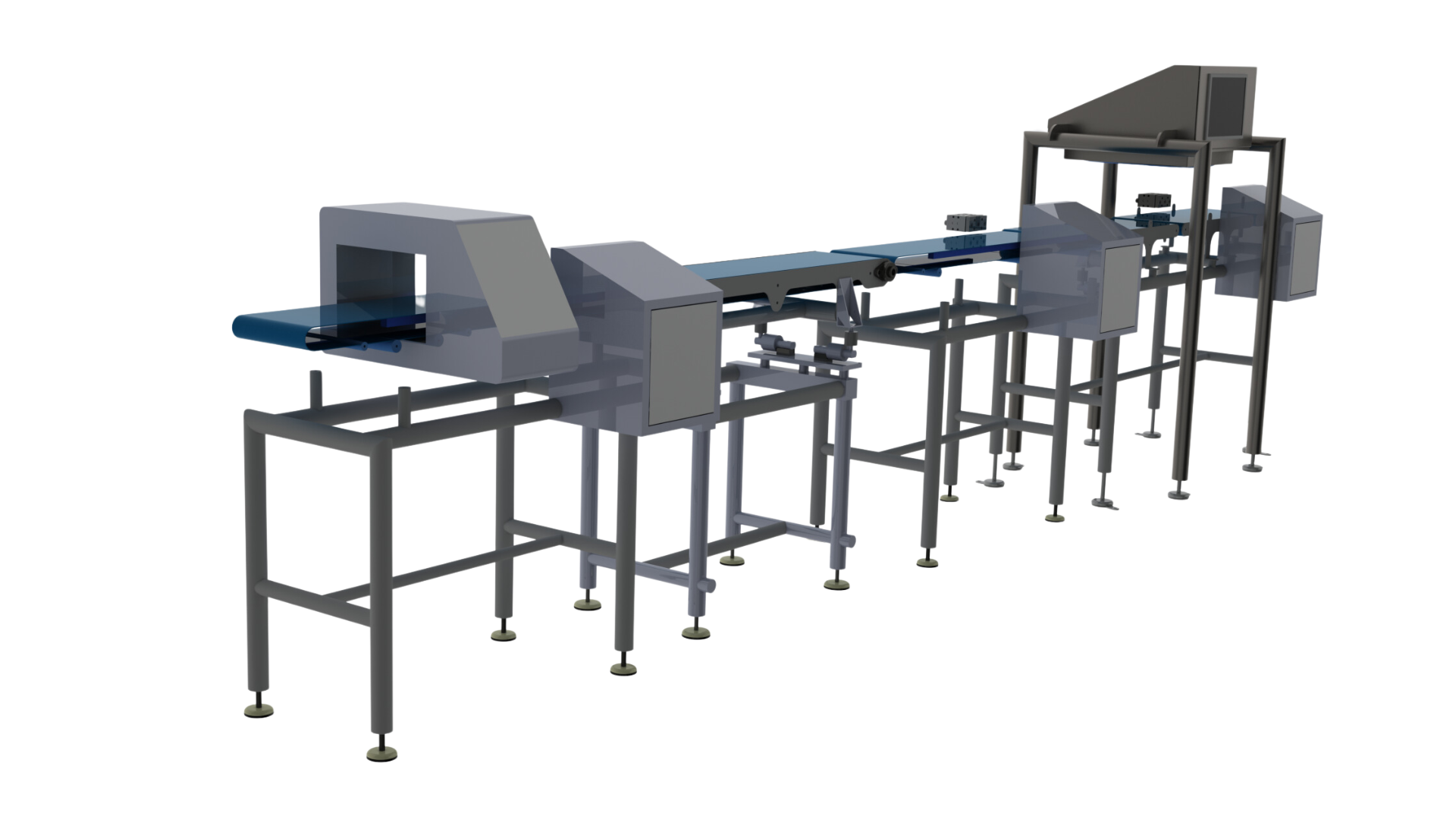

Metal Detection and Dynamic Weighing Station:

In the cartooning area, we offer the option of two configurations:

We can implement metal detection and dynamic weighing stations as two independent units, each with its own closed reject system. This configuration offers maximum flexibility and allows precise control of each stage of the process.

We also offer the option of a compact station where we integrate metal detection and dynamic weighing in series, with two individualized rejects in the same station at the dynamic weighing output. This optimized configuration saves space and simplifies the process, ensuring high efficiency without compromising quality.

Vision Inspection with Deep Learning:

Our vision inspection system with Deep Learning represents the latest innovation in quality control, enabling accurate defect detection and classification in real time. With an exceptional ability to identify imperfections and anomalies, our system ensures that only the highest quality products move through the production line. For more information go to the ONE VISON Inspection – Packaged Product Inspection category.

Individualized rejection for each station:

Defective or out-of-specification products are automatically diverted to each individual locked compartment individualized to discriminate each type of reject, either by metal detection, weighing, or quality control by machine vision with Deep Learning , avoiding unnecessary interruptions and maximizing operational efficiency.

Customization and Flexibility:

We recognize that every production environment is unique, so our solutions are designed to be highly customizable and adaptable to each customer’s specific needs. Whether it’s materials of construction, equipment configurations or integration of additional technologies, we work closely with our customers to ensure that our solutions meet their exact requirements.

At IFS, our mission is to deliver leading-edge solutions that drive operational excellence and promote our customers’ long-term success. With our focus on innovation and commitment to quality, we are ready to help you take your production to the next level.