Packaged product inspection

- Estás aquí:

- Inicio

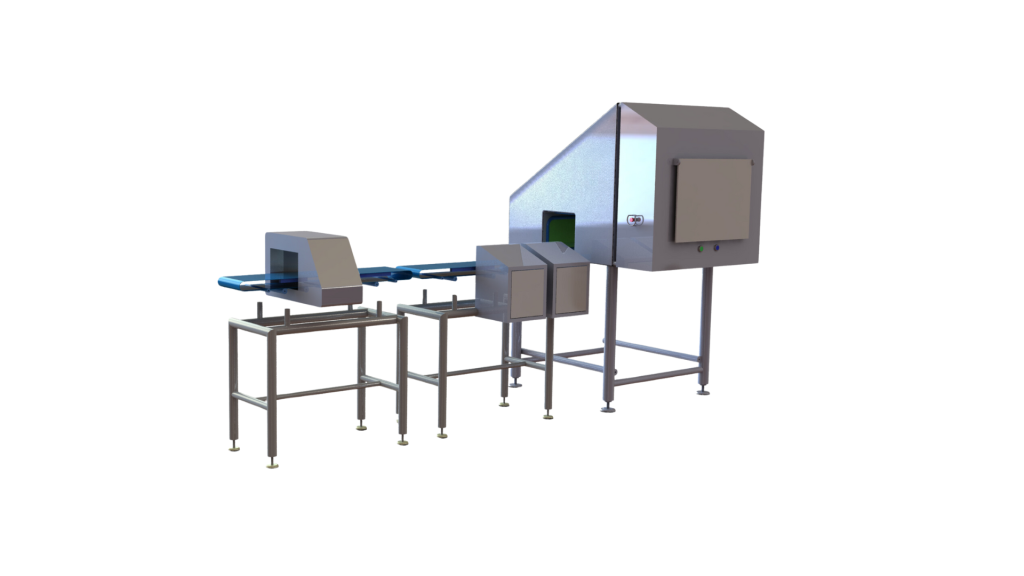

- One Vision Inspection System Packaged product inspection

System features

Inspection Sealed:- Detection of: Product in sealing area, foreign bodies, sealing defects with thermal cameras, lid centring control... etc.

- Speed up to 300 containers/minute.

- Detection of: Unreadable marking, marking error, label control (positioning and content), QR code/barcode reading.... etc.

- Speed up to 300 containers/minute.

Packaged product inspection

Introduction:

Welcome to the leading edge of product inspection in the packaging industry and the revolution in tray seal inspection. Our revolutionary systems redefine accuracy and reliability in both pack sealing area assessment and pouch heat sealing, ensuring the quality of every product leaving your production line and guaranteeing integrity and safety.

Outstanding Features:

Equipped with state-of-the-art technology, our systems inspect every millimetre of the sealing area with extraordinary resolution and outstanding thermal accuracy, identifying even the smallest imperfections and minute temperature variations.

From seal irregularities to micro-leaks, our systems detect defects at multiple levels, guaranteeing product integrity and customer satisfaction, and ensuring uniformity in heat sealing to avoid problems that could affect product quality and safety.

Whether you work with plastic, aluminium or other materials, our systems adapt to provide effective inspection on any type of packaging, while maintaining consistent quality standards.

Both seal and thermal inspection are performed in real time, allowing for immediate correction, and preventing defective products from reaching the market.

Easily integrated into your production line, you can choose a complete system with in-line transport and rejection or simply perform defect inspection at the sealing die. It offers a comprehensive solution to improve the quality and efficiency of your production.

Benefits to your Production:

Robustness, confidence in product quality:

Ensure the quality of each product, strengthening customer confidence in your brand, and benefit from increased reliability in heat sealing, guaranteeing the freshness of each product.

Reduce waste:

Minimise product loss by identifying and correcting sealing or heat-sealing problems before they reach the market, thereby raising quality and efficiency standards.

Regulatory Compliance:

Meet the most stringent regulations and quality standards, ensuring regulatory compliance with every production batch and ensuring compliance with local and international regulations.

Find out how we can improve your production process and ensure perfection in every tray, tray or bag that leaves your line. Contact us for a personalised demonstration and discover the next generation in sealing and heat-sealing inspection.

Applications: